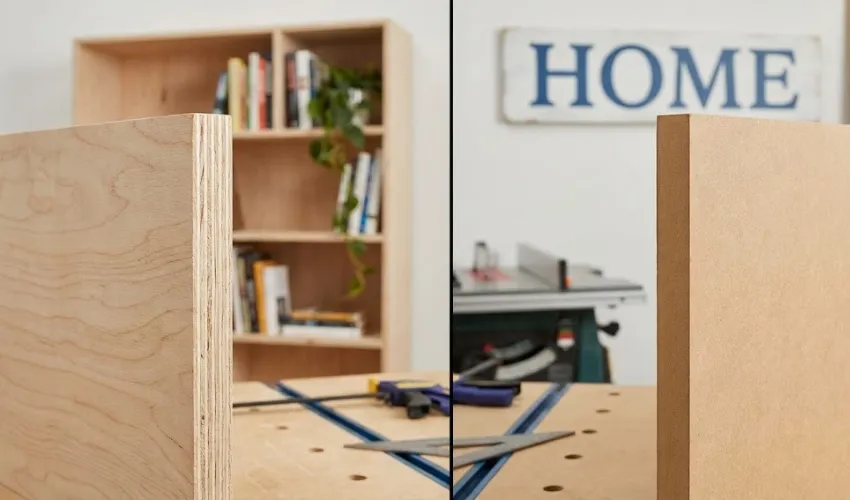

The Problem Every DIYer Faces

You’re standing in the lumber aisle, staring at two similar-looking wood panels with wildly different price tags. The clerk mentions “MDF” and “plywood,” but which one actually makes sense for your bookshelf? Your painted headboard? That bathroom vanity you’ve been planning? Buy the wrong material, and you’ll either overspend or watch your project sag, swell, or off-gas formaldehyde into your bedroom for months.

Here’s what you’ll learn: The real-world differences between plywood and MDF, when each material wins, the hidden traps that catch beginners, and how to choose certified low-VOC options that protect your family and your budget.

The Quick-Reference Comparison Table

| Factor | Plywood | MDF |

|---|---|---|

| Cost | Higher upfront—often 1.5–2× MDF in many markets | Cheapest sheet goods available for furniture/cabinetry |

| Durability | Strong screw-holding, resists sagging, 15–25 year lifespan when kept dry | Moderate strength, poor screw-holding, prone to sagging and edge damage; 7–10 year typical lifespan |

| Moisture Resistance | Good (exterior/marine grades excel in damp conditions) | Poor—swells badly with water, crumbles at edges |

| Surface Finish | Visible grain and potential voids; requires sanding/filling for smooth paint | Ultra-smooth, uniform surface—perfect for painted finishes |

| Eco-Friendliness | Uses more solid wood; available in E0/E1 low-formaldehyde; longer life = less landfill | Efficient use of wood waste; typically high VOCs unless CARB-II/E0/E1 certified |

| Best For | Load-bearing shelves, bed frames, cabinet boxes, moisture-prone areas | Painted decor, craft signs, moldings, detailed routing work |

When Plywood Wins: Strength and Longevity Projects

Load-Bearing Furniture Demands Real Structure. Plywood’s cross-laminated layers create genuine strength that resists sagging under weight. If you’re building bookshelves, bench seats, bed frames, or cabinet carcasses that need to support heavy loads without bowing over time, plywood delivers reliable performance for 15–25 years when kept dry.

Moisture-Prone Zones Require Resilience. Planning a bathroom vanity or kitchen cabinet? Exterior or marine-grade plywood tolerates humidity and occasional water exposure far better than MDF. However, mere resistance isn’t always enough for every zone.

knowing how to choose the best moisture-resistant materials versus truly waterproof ones is critical to ensure your project doesn’t rot. Standard interior plywood still handles ambient moisture better than MDF, making it the smarter choice near windows, in laundry rooms, or anywhere condensation occurs.

Long-Life Investment Pieces Pay Off. Plywood costs 1.5–2× more upfront, but it typically lasts twice as long as MDF in similar conditions. For furniture you’ll move multiple times—kids’ storage units, desks, wall panels—the durability justifies the price difference.

Mechanical Fastening Holds Firm. Screws and nails bite into plywood’s wood layers and stay put. You can disassemble and reassemble plywood furniture without stripping out screw holes, a major advantage for projects you might need to modify or relocate.

When MDF Wins: Smooth Finishes and Budget Crafts

Paint-Ready Perfection Straight from the Store. MDF’s ultra-smooth, uniform surface eliminates visible grain, knots, and voids. If you’re creating painted signs, wall letters, decorative trim, or moldings where a glass-smooth finish matters, MDF saves hours of filling and sanding compared to plywood.

Budget-Friendly Indoor Projects Make Sense. For non-structural pieces like wardrobe doors, headboards, internal shelves, or display units that won’t carry heavy loads, MDF’s lower cost (among the cheapest sheet goods available) keeps your project budget under control.

Detailed Routing and CNC Work Stays Clean. MDF’s consistent density throughout prevents tear-out and splintering during intricate cuts. If you’re creating raised-panel effects, carved patterns, or laser-cut craft pieces, MDF machines beautifully without the unpredictable grain direction of plywood.

Low-Stakes Indoor Furniture Fits the Profile. For items you might replace in 7–10 years—temporary furniture, kids’ play pieces, seasonal decor—MDF’s shorter lifespan becomes less of a concern when the upfront savings matter more.

The Hidden Traps That Catch Beginners

Plywood Misconceptions

“Waterproof” Doesn’t Mean What You Think. Standard interior plywood still swells, delaminates, and grows mold with long-term moisture exposure. Only exterior or marine grades truly tolerate sustained damp conditions—don’t assume any plywood panel will survive bathroom steam or outdoor use without the proper rating.

Face Quality Varies Dramatically. Low-grade plywood contains voids, patches, and rough grain that telegraph through paint no matter how much you sand. For visible faces, invest in A/B grade plywood or budget extra time for extensive filling and surface prep.

Sharp Blades Are Non-Negotiable. Plywood’s cross-grain layers splinter easily with dull saw blades. Plan for crisp cuts by using sharp, fine-tooth blades and consider edge banding to hide the layered edges on visible surfaces.

MDF Dangers

Indoor Air Quality Becomes a Real Concern. Conventional MDF uses urea-formaldehyde resin that off-gases formaldehyde for months or years, especially in warm, poorly ventilated rooms. For bedrooms, nurseries, or enclosed spaces, this isn’t just unpleasant—it’s a documented health risk that affects breathing and sleep quality.

Moisture Is MDF’s Kryptonite. MDF swells badly when wet, and unlike plywood, it doesn’t recover when it dries. Edges crumble under screws and nails in humid conditions, and long shelf spans sag over time even with moderate loads. Bathrooms, kitchens, and outdoor applications require extreme caution or alternative materials entirely.

Fine Dust Creates Workshop Hazards. MDF generates clouds of ultra-fine dust when cut that stays airborne longer than wood dust. Always wear a respirator (not just a dust mask) and use proper dust collection to avoid respiratory irritation.

The Eco-Impact and Budget Reality Check

Plywood’s Sustainability Profile. Plywood uses more solid wood per panel, which raises concerns about forest consumption. However, certified low-formaldehyde plywood (E0/E1 ratings) dramatically reduces VOC emissions, and the 15–25 year lifespan means less frequent replacement and reduced landfill waste over time. The “buy once, keep for years” approach aligns with eco-conscious consumption.

MDF’s Efficient but Problematic Formula. MDF efficiently uses wood waste and sawdust, reducing forest pressure at the material sourcing level. But the urea-formaldehyde binder system creates higher VOC off-gassing unless you specifically purchase CARB Phase 2, EPA TSCA Title VI, or E0/E1 certified panels—which typically cost 20–30% more than standard MDF.

The Certification Labels That Actually Matter. When buying either material for indoor projects—especially children’s rooms, bedrooms, or enclosed craft spaces—look for panels explicitly rated E0/E1, CARB Phase 2, or EPA TSCA Title VI. These certifications indicate significantly lower formaldehyde emissions, transforming both materials from potential health concerns into safer choices for home environments.

True Cost Calculation. MDF wins for immediate budget relief, but plywood’s longer lifespan changes the math. A $40 plywood shelf lasting 20 years costs $2/year; a $25 MDF shelf replaced after 8 years costs $3.12/year. For high-use furniture, plywood’s upfront premium becomes the economical choice over time.

The Verdict: Match Material to Mission

Choose Plywood When:

- Structural integrity matters (shelves holding books, bench seats, bed frames)

- Moisture exposure is possible (bathrooms, kitchens, near windows—use exterior/marine grades)

- Longevity justifies cost (furniture you’ll keep for decades or move multiple times)

- Screw-holding strength is critical (cabinet carcasses, heavy-use storage)

Choose MDF When:

- Painted finish is the priority (craft signs, wall letters, decorative trim)

- Budget is extremely tight (temporary furniture, low-stakes indoor projects)

- Intricate routing/cutting is required (raised panels, carved details, CNC work)

- Load and moisture are minimal (wardrobe doors, internal shelves, display units)

For Eco-Conscious DIYers: Highlight low-formaldehyde plywood as your “pay once, keep for years” structural choice, and certified low-VOC MDF for small, indoor, painted craft decor. Both options fit sustainability narratives when you choose the right certifications and match material properties to project demands.

Your next project deserves the right foundation—choose based on how you’ll actually use the piece, not just the price tag at checkout. Still planning your build? Check our Budget DIY Hacks category for practical projects using both materials, complete with cut lists and finishing techniques.